Windowless two-cavity solar reactor design

Short description

Design of a versatile indirectly heated high temperature solar reactor without a window. Specific knowhow includes suitable materials and shapes accepting the concentrated solar irradiation and the high temperature gas sealing of these materials.

Main technical features

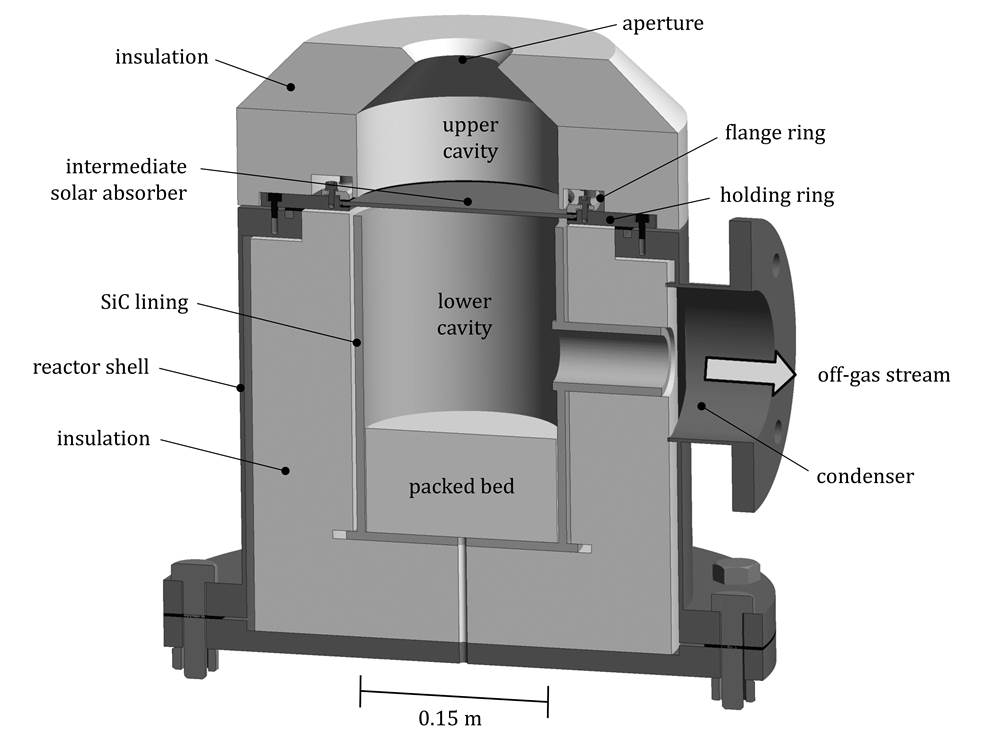

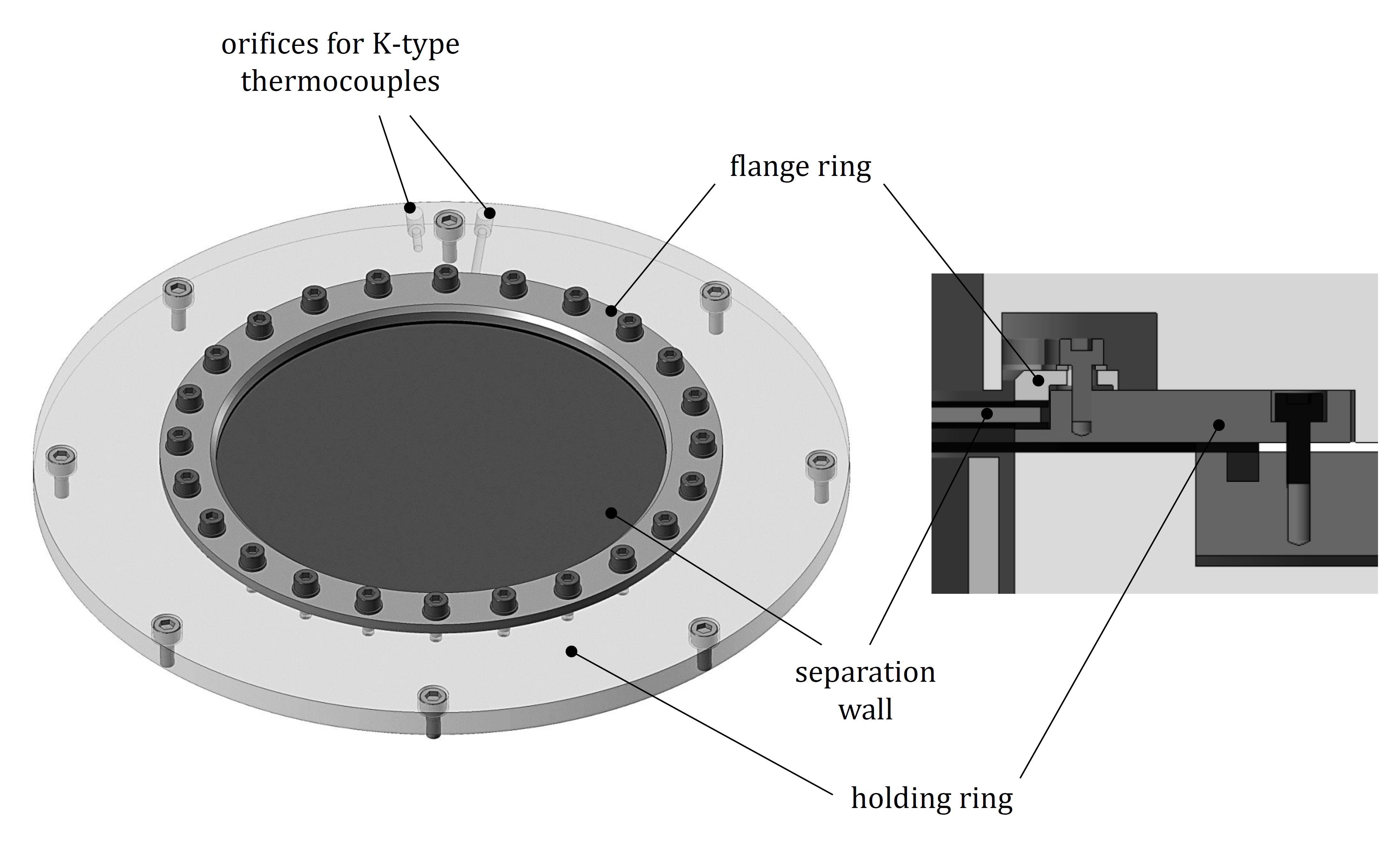

In the two-cavity reactor developed at PSI concentrated solar radiation enters vertically (“beam-down radiation”) an upper cavity which is separate by a thin ceramic absorber plate from the lower cavity underneath, in which the feedstock to be processed is placed and from which the product gases are leaving through an outlet pipe (see image). This versatile reactor type has been demonstrated for different thermochemical processes like the solar thermochemical production of Zn from ZnO and the solar steam gasification of carbonaceous materials on laboratory scale (see publications sol_128... and Fuel Processing Technology..) as well as on pilot scale (see publications sol_129.. and Energy&Fuels..). In all cases the solar reactor was sealed against the ambient air by a quartz window on top of the upper cavity. These windows are however fragile components and they are also limiting the scale-up options due to the fact, that they are only available in restricted sizes. The new design allows to avoid the quartz window. For this the requirements for the absorber materials between the cavities are more severe as in the windowed design. Also the hot sealing constitutes a significant challenge.

Innovative aspects

In contrast to the two-cavity solar reactors design, that has been demonstrated up to pilot scale, the improved design allows to avoid the quartz window. The sealing towards the environment is newly done via a hot sealing of the ceramic emitter body between the two cavities.

Applications

The two-cavity reactor design for packed-bed processing is a versatile design, that has up to now been demonstrated for solar carbothermal reduction of ZnO, for solar treatment of Waelz Oxide and for solar steam gasification of carbonaceous wastes and other feedstocks (see attached publications). The solar reactor is suited to be used for numerous further processes heated by concentrated solar irradiation involving solid-solid or solid-gas reactions.

Related documents

Image gallery

Type of partner sought

Companies,Research organizationsTasks to be performed by the partner you are looking for.

The envisioned partner should be interested to optimise the new technology and to scale it up.