Dynamic modelling of thermal desalination plants for coupling with CSP

Short description

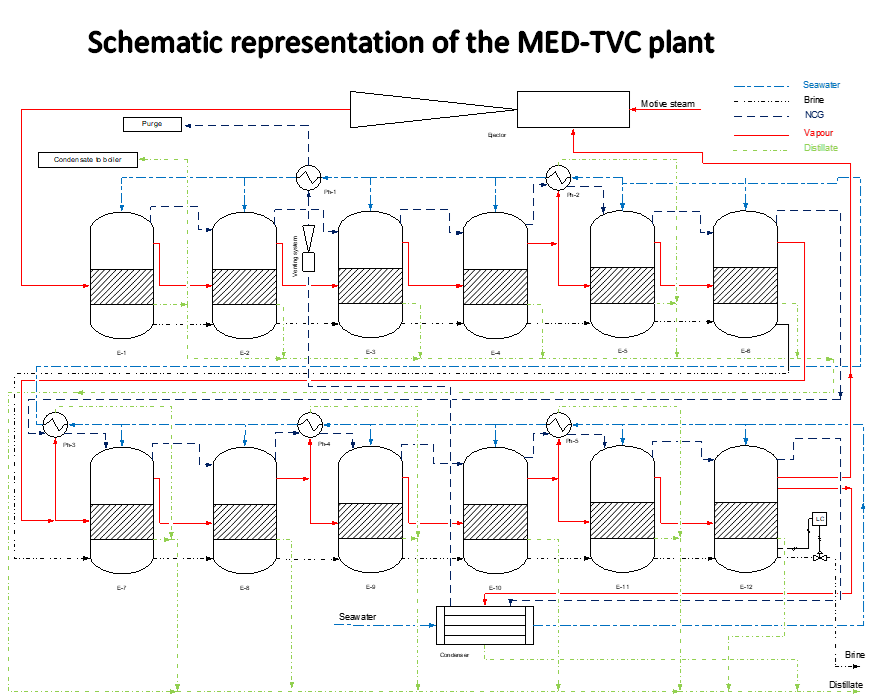

The Multi Effect Distillation (MED) technology is a key actor for the construction of new evaporative desalination plants. This is especially important when solar-powered cogeneration schemes are applied. With this regard, the analysis of transient behaviour requires the development of dynamic models for the MED process and relevant implementation such as the MED-TVC.

No easily available dynamic modelling tool can be found in the literature, and the few modelling papers available, refer to works in which several simplifying assumptions and constrains are still made, thus limiting their potential use.

In the last years, the UNIPA team has worked on the development of equation-based dynamic modeling tools for the simulation of transient operation of MSF and MED plants, with a specific focus to the scenarios where the plant is powered by low-temperature solar energy.

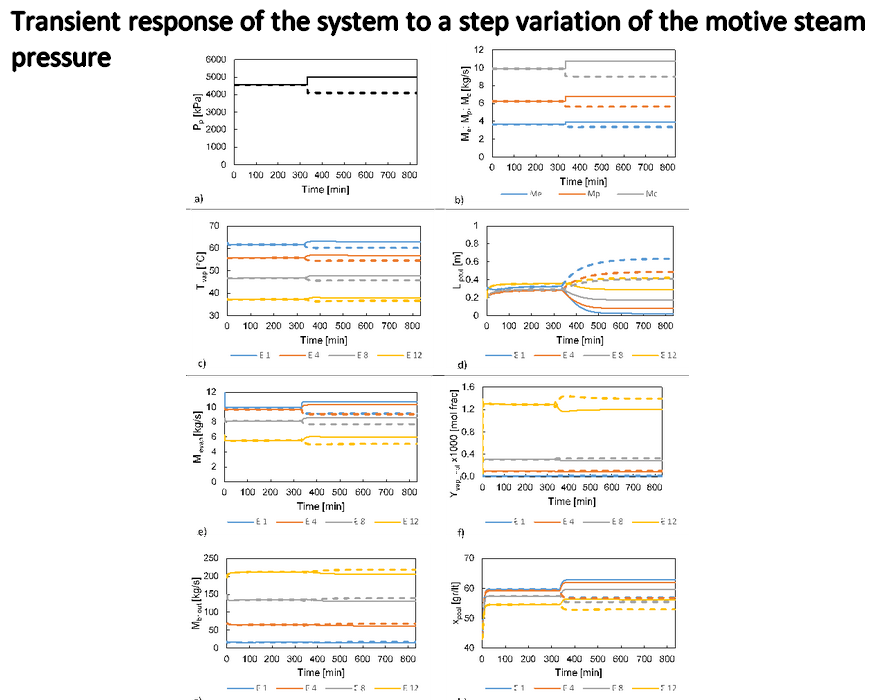

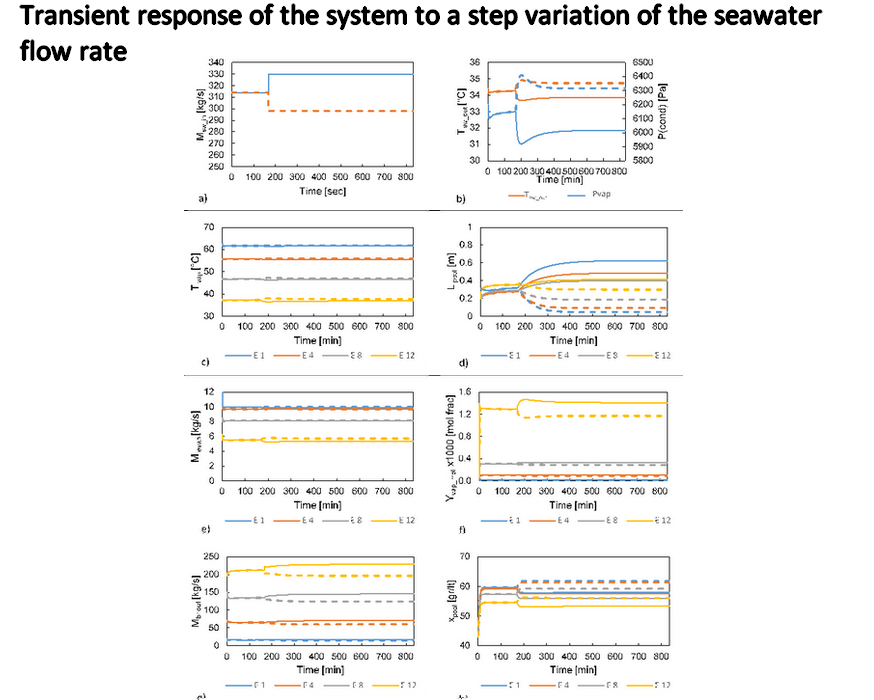

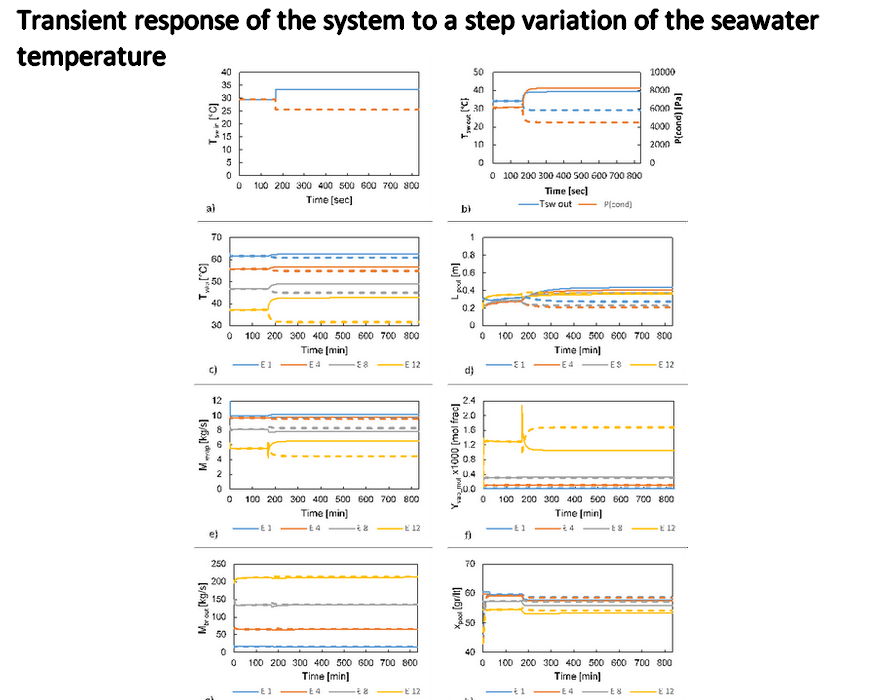

Looking in particular the the most advanced and interesting model for the MED-TVC process, it addresses most of the aspects still limiting previous models formulations. The powerful equation-based process simulator gPROMS® was chosen for the implementation of the model, developed on the basis of available data from a MED-TVC plant located in Trapani, Sicily (Italy). After validation, the model was used for some preliminary analysis of system behaviour under transient conditions, artificially generated by implementing specific disturbances such as the variation in the motive steam pressure, seawater feed flow rate and temperature. This demonstrates the model capability to describe in details the dynamic response of the system with respect to all its variables, thus representing a useful tool for the prediction of transient operations and control system design purposes of MED-TVC plants.

Main technical features

The model presented here is based on the configuration of the MED-TVC plant located in Trapani (Italy), which allows its validation using actual data from that plant. The main features of the model are:

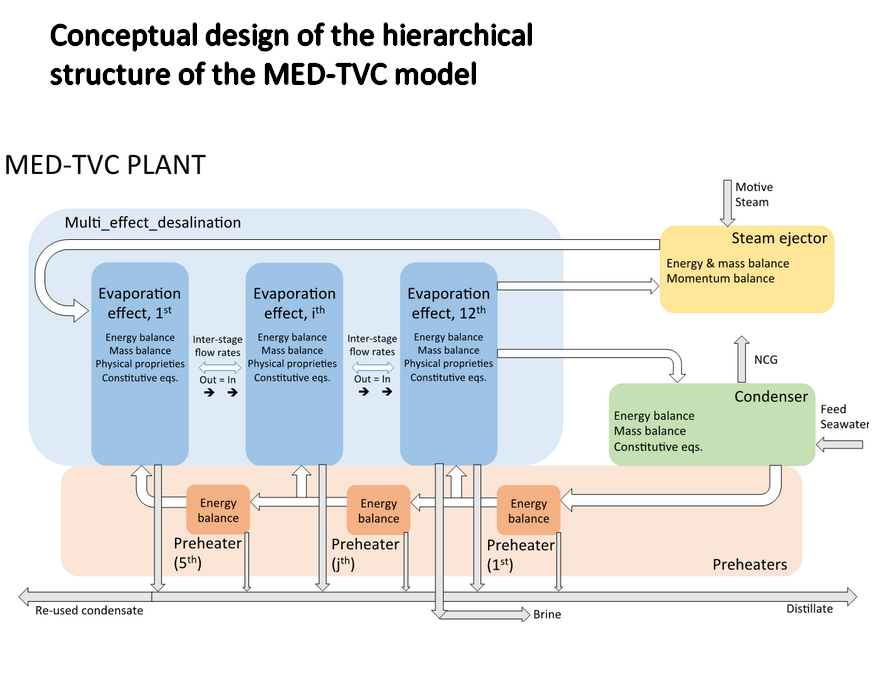

- It follows an hierarchical structure with three levels of modelling: the lowest for the single evaporation effect, the middle level for each component (Multiple Effect Distillation, preheaters, steam ejector, and end condenser), and the highest level for the complete MED-TVC unit.

- The model has been implemented in the software environment gPROMS®, an equation-based dynamic simulator.

- The model is based on first order ordinary differential equations together with algebraic equations, which constitute the mass balances, energy balances, and heat transfer equations on each modelling level considered.

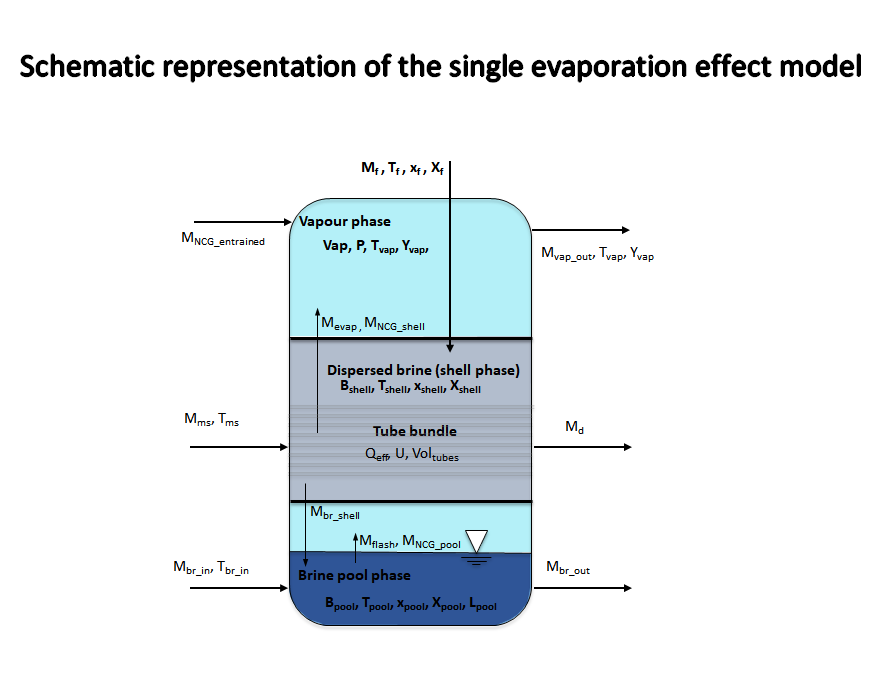

- It accounts for inherent complex phenomena of this process, such as the presence of Non-Condensable Gases (NCG), dynamic connections between effects, partial vapour condensation, brine pool levels variation, the use of preheaters, and a more accurate thermocompressor modelling based on first principle equations (rather than empirical correlations).

- It considers the presence of three different phases inside the effects: (i) brine pool, (ii) seawater/brine dispersed around the tube bundle, and (iii) the vapour phase, as a mixture of vapour and NCG.

Innovative aspects

The developed novel dynamic MED model improves previous research works in the following aspects:

- It takes into account the presence of Non-Condensable Gases (NGC) within effects, which greatly affects the heat transfer process in the evaporators.

- The majority of previous dynamic MED models consider complete vapor condensation inside evaporators. In this new model, the partial condensation of the vapor is accounted, which more accurately reflects what occurs in the real process.

- The thermocompressor is modelled using first principles equations, while most of the previous models consider empirical or semi-empirical correlations. This improvement help to increase the reliability of the model.

- The model presented has a hierarchical structure, unlike other models, which enhances its flexibility when changing the number of effects and facilitates the implementation in any modelling platform.

Applications

The developed model is an useful tool for the theoretical analysis of transient operations and for the design of control systems in MED-TVC desalination plants.

Related documents

Image gallery

Type of partner sought

Companies,OtherTasks to be performed by the partner you are looking for.

We are looking for industrial companies willing to collaborate in the validation of the results obtained by providing actual data from a MED-TVC plant.