Thermal characterization of air absorber samples

Short description

In the framework of the STAGE-STE project, the Solar Thermal Energy Department at CENER has developed a solar simulator test bench for evaluating volumetric absorber samples at laboratory scale.

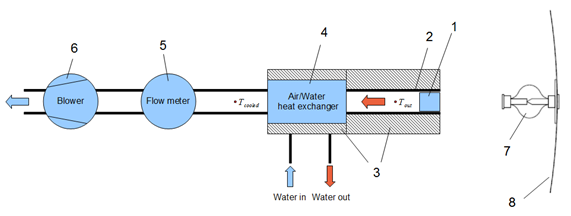

The test loop can be explained as follows (see below figure): The volumetric absorber sample (1) is mounted at the inlet of the air duct/receiver pipe (2). The ambient air is forced through the experimental circuit by the blower (6). In particular, the air is forced through the absorber sample (1), the receiver pipe (2), the air/water heat exchanger (4) and the flow meter (5). The absorber sample (1) is irradiated by concentrated light of a xenon lamp (7). The heat exchanger and the receiver unit are insulated (3) in order to keep thermal losses as low as possible.

Main technical features

The test of each sample takes between 6 to 8 h. During this time the irradiation is kept constant. To achieve various air outlet temperatures, the mass-flow is varied four times. At the start-up, the highest value is set to avoid thermal shocks. After each step, the mass flow is kept constant between 90 to 120 min to reach thermal equilibrium. The reason for this long period is that despite the air achieves the steady state quite quickly, the water of the heat exchanger needed more time to get steady conditions. Once the steady state is reached, the temperatures and the radiation data is taken to characterize this steady state period. After 4 steps the lowest mass flow is set with the corresponding “hottest” operating point. Then, each sample is tested at least three more times to demonstrate a general repeatability of the efficiency measurement. For the different measurements carried out, the K-type thermocouples used have a maximum error of 1.5 °C and the PT100 sensors used in the heat exchanger had a maximum error in the working range of less than 0.25 °C.

Innovative aspects

The main innovative aspect is the feature of sample specific mounting adaptors. This allows testing of innovative stacked plate absorber samples.

Applications

The developed solar simulator test bench can be applied for any other volumetric absorber sample.

Related documents

Image gallery

Type of partner sought

Companies,Research organizationsTasks to be performed by the partner you are looking for.

Cooperation in terms of sample testing and validation of efficiency measurements.