Smartblades

Short description

Nowadays, wind turbine rotor blades can reach up to 85 meters in length and the turbines themselves can tower more than 200 meters above the ground. Consequently, rotor blades are subject to severely fluctuating wind loads due to the difference in wind distribution close to the ground and at the top end of the turbine. The result is high loads for the rotor blade material and an enormous challenge when it comes to the control system. In the case of storm winds in particular, the wind load can be so large that turbine operators are even forced to power the systems down in order to avoid damage. From a cost-efficiency perspective that is particularly bad, as stronger wind translates to higher energy yields. The ideal solution would be rotor blades, which are able to adapt their geometry to suit the local wind conditions. This is made possible by active and passive technologies which allow individual rotor blades to adjust to the prevailing wind conditions – so-called smart blades. The Smart Blades project – in a joint effort between researchers from the German Aerospace Center (DLR), Fraunhofer IWES and ForWind, the Center for Wind Energy Research of the Universities of Oldenburg, Hanover and Bremen – aimed at investigating the effect of these technologies. The findings of this project offer turbine developers and operators new information and tools allowing them to launch more effective, more costefficient and more reliable system designs on the market.

Main technical features

- Bend twist coupling

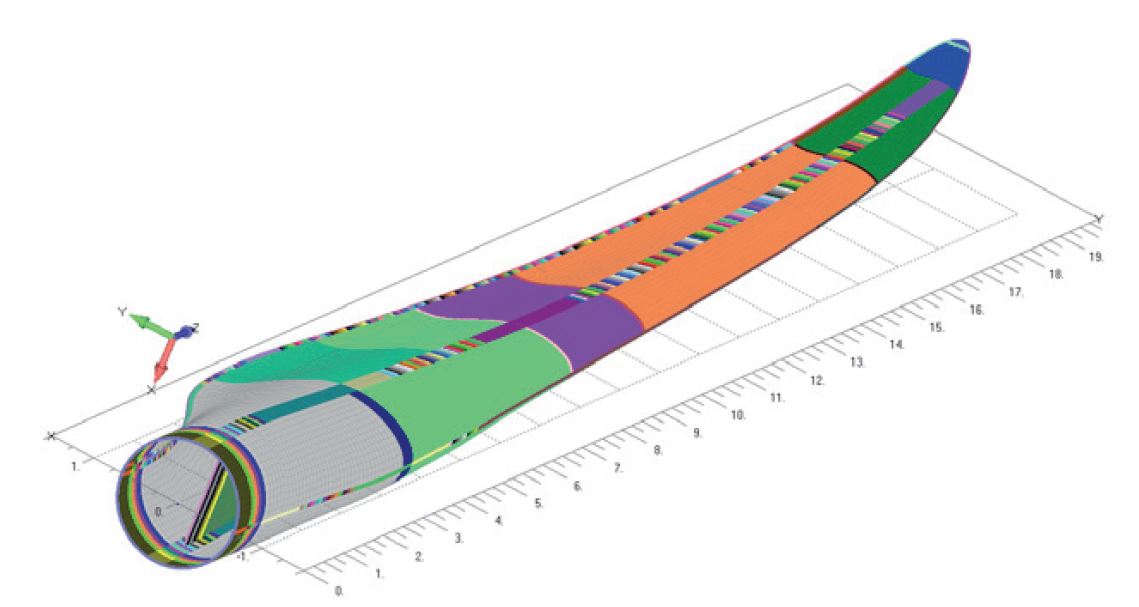

When a rotor blade – subject to high wind – turns in such a way that it offers the wind a smaller contact surface, researchers speak about end-twist coupling (BTC). As this bending is initiated by the force of the wind alone, it is described as a “passive” mechanism. The investigation focused on two approaches which produce this effect. On the one hand, a crescent-shaped geometry was examined and, on the other, a particular structure was employed for the material composition of the rotor blade. In this structural approach, the glass fibres within the rotor blade layup are arranged in such a way that they induce local drilling rotations on top of the global blade pitch at different wind speeds “The advantages of the mechanisms are that the blades can be built with a less robust design and are therefore lighter. Both processes have the potential to improve the energy utilization of wind power systems,” says Alper Sevinc, who was Smart Blades technology coordinator for the bending-torsion coupled rotor blades at Fraunhofer IWES. The researchers now hope to be able to investigate the mechanisms tested in the simulation on already designed demonstration rotor blades in the upcoming project SmartBlades2.0.

- Active control elements in the rotor blade

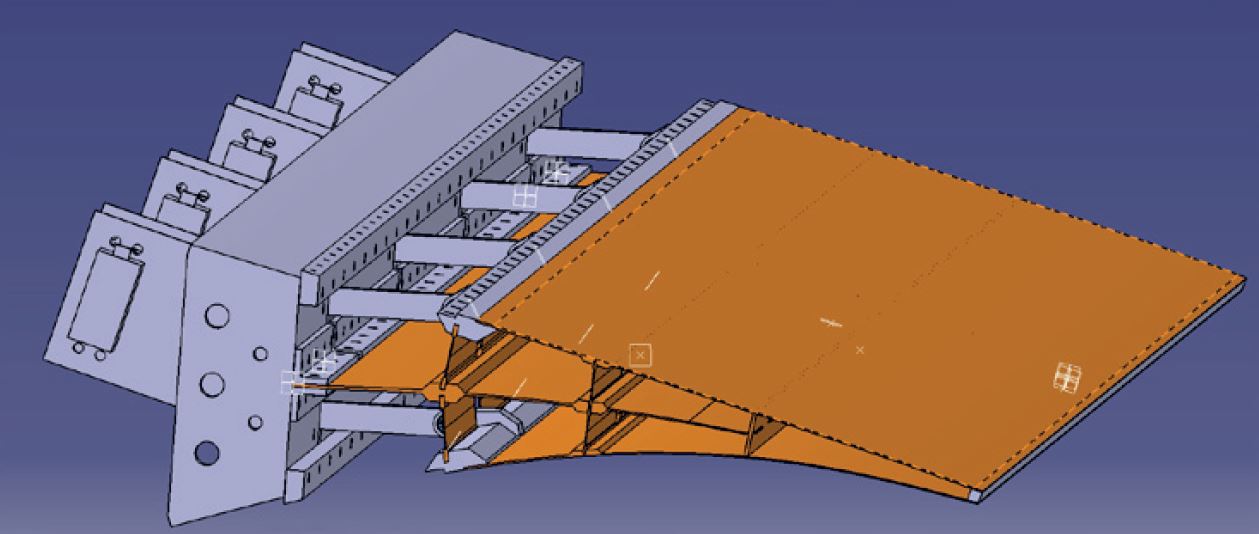

Another approach pursued by the scientists applies active mechanisms which adapt the trailing edges of a rotor blade and which system operators can use to control the aerodynamic loads on a rotor blade. In this respect, the researchers examined both flexible and rigid trailing edge flaps. The concept was inspired by the aviation industry and is comparable to the flaps on the wings of aircrafts. The investigations revealed that both options effectively reduce the load on the rotor blade. However, the maintenance efforts required for rigid trailing edge flaps are so high, due to the soiling of the moving parts, that the advantages of flexible trailing edge flaps outweigh them substantially. The construction of demonstration blades for this concept is also planned at a later point. However, in a next step within SmartBlades2.0 this technology shall prove its effectiveness and reliability on segment level under real environmental conditions.

- Flexible leading edge flaps create an optimal profile

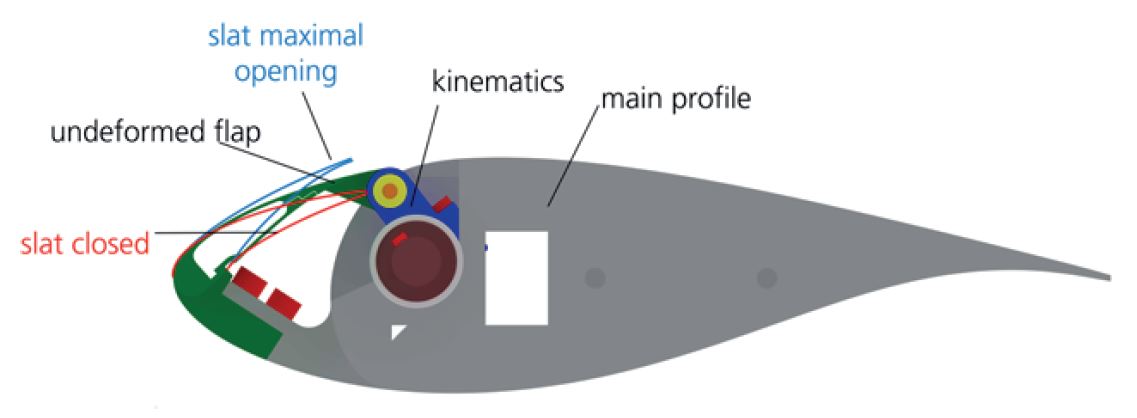

The researchers also considered whether a flexible leading edge flap on a rotor blade can improve the efficiency of wind turbines subject to heavily fluctuating, turbulent wind conditions. This mechanism enables optimal use of a rotor blade in a large wind speed range. “The advantage in this respect is in the reaction speed of the flexibility of the leading edge flap, which allows on rapidly influencing the active aerodynamic forces in turbulent influx conditions,” says Michael Hölling, Smart Blades technology coordinator for rotor blades with flexible leading edge flaps at ForWind, commenting of the potential of the adaptive leading edge flap. The concept of the flexible leading edge flap was tested in a wind tunnel during the past project and delivered very promising results for further investigations in the future project.